The processes for manufacturing and forming (composite) structures made of paper and board are used millions of times a day. Nevertheless, design and layout are still mostly based on empirical knowledge. Extensive scientific studies of the processes and the use of modern methods and simulations, which are already regularly used in other industries and with various other material systems, are still an exception here. This comparatively low level of development contrasts with constantly increasing requirements. In addition, questions of sustainability and climate protection are playing an increasingly important role and offer great growth potential for this industry in particular.

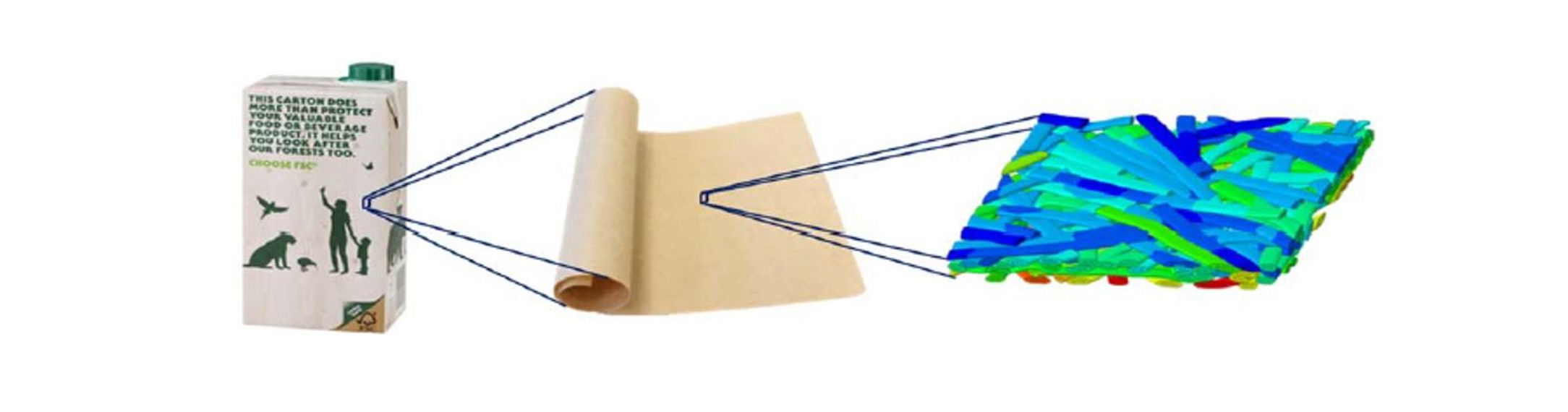

The aim of this project is therefore to significantly improve the utilization of the lightweight potential of paper and board in various industrial applications by using innovative measurement techniques as well as new simulation methods. In particular, the consideration of the influence of fluctuations and defects in the fiber network structure on the global behavior is aimed at by means of multi-scale simulation models. At the same time, the consideration of recyclability in the modeling makes it possible to achieve a significantly increased degree of recycling.