Paper physics and metrology

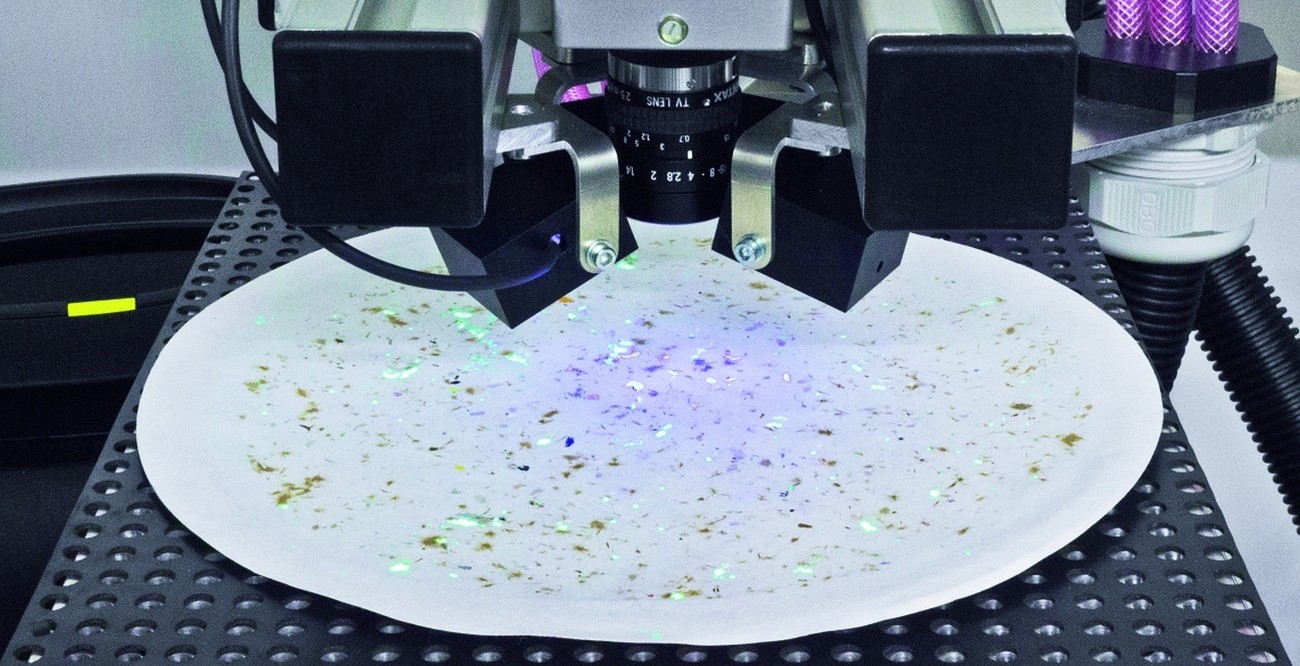

For the evaluation of processes in the stock preparation and paper production different measuring methods and adapted analytical techniques are needed. A wide range of different measurement and analysis methods are available at our department. Besides the application of well-established measurement methods, we are actively working on the development of new measurement and analysis methods. For most of these projects, image analysis plays an important role, because multiple techniques for the creation of pictures are available and powerful computers enable effective evaluation algorithms for these pictures.

Selected Examples from our activities are the analysis of morphological fibre properties by fuzzy clustering algorithms, the highly precise wire mark analysis and determination of local deformation under tensile strain.

The Fibre-Class-Algorithm developed at PMV uses fuzzy clustering methods to condensate and interpret data from an image-based fiber analysis system. These data can be correlated with process parameters if needed. Camera-based fiber analysis systems provide many data. The software of commercial systems condensates these data so strongly to mean values, standard deviations, and similar sum parameters, that they cannot be correlated with variations in the process or the product. Our approach uses the original data to evaluate specific issues with intelligent algorithms. Once these algorithms are trained, such systems can be used to control the process or quality. Figure XX shows how such methods can be used in a pulp mill to predict the strength properties from morphological data from the pulp.

Another field where fuzzy clustering algorithms are used in image analysis is the wire mark analysis.

In the last years, the PMV succeeded to improve the algorithms so far, that the precision of the evaluation was raised significantly and the wire mark analysis can be used for automated process and quality control. For example with today’s algorithms, it is possible to gain information about the different layers of upper and lower wire of modern gap formers.