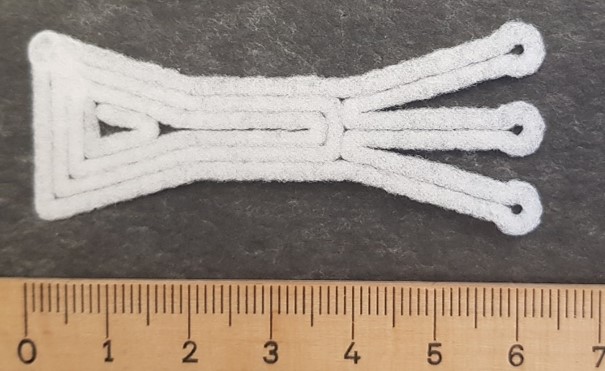

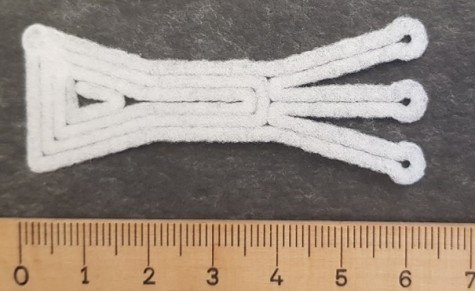

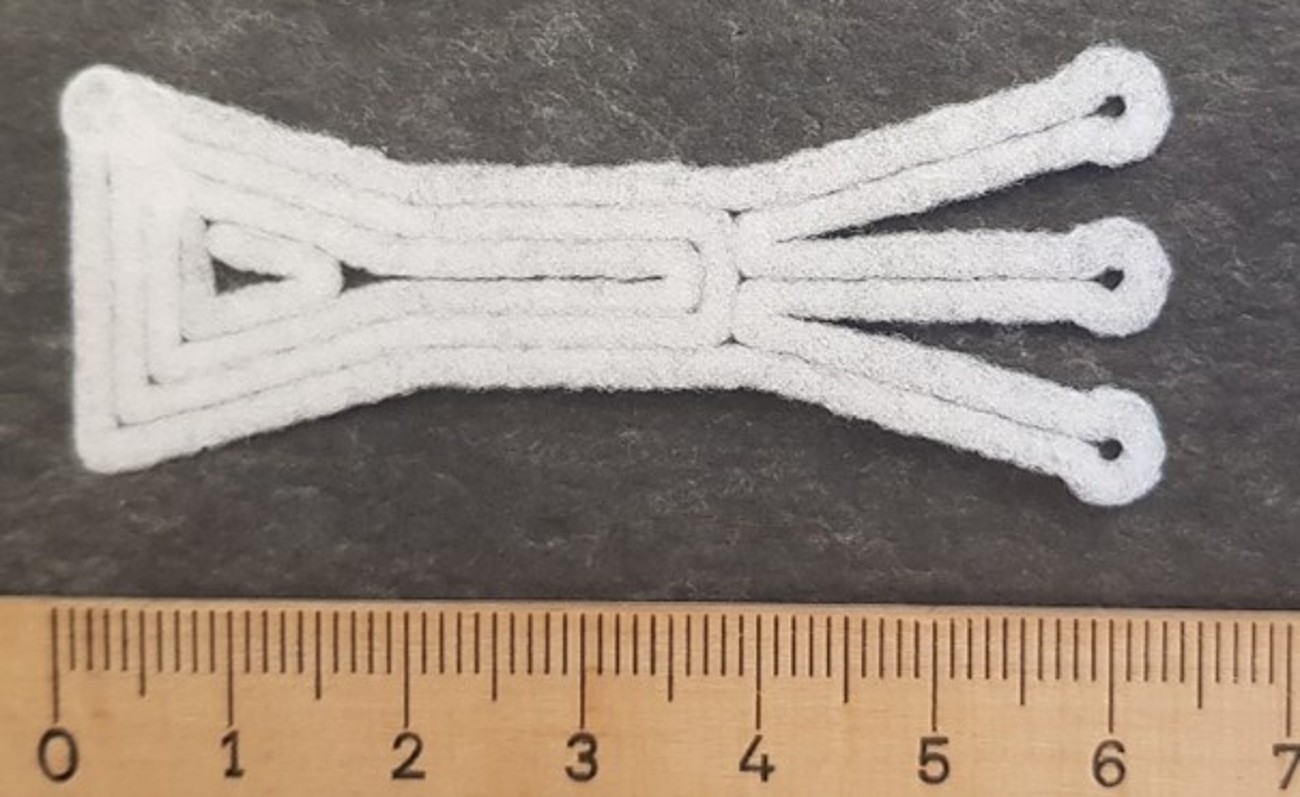

As in paper production, a fiber suspension is applied to a screen. However, the suspension flows through a nozzle that moves in the plane above the screen. This makes it possible to deposit the fibers in a controlled manner. In addition to the location of the fiber deposit, the fibers can also be placed oriented in the direction of travel. This combination enables completely new properties that cannot be realized in conventional papermaking. By using different storage containers, the layers can also be made up of different fiber materials or fiber blends. In addition to fiber materials, it also seems possible to use fillers to subsequently densify the fiber structure.

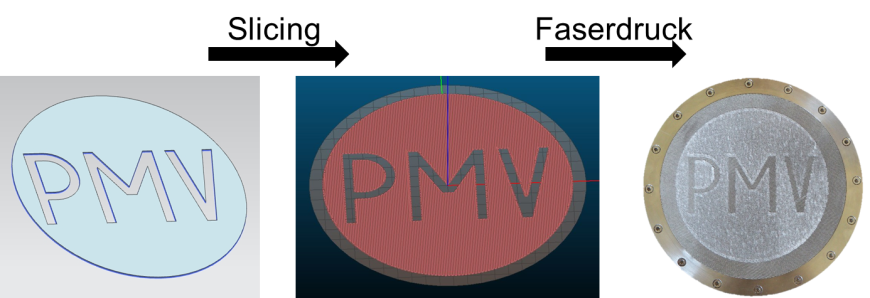

As in additive manufacturing, solid bodies are divided into layers during slicing and a route for fiber application is defined for each layer. The subsequent properties of the sample are significantly influenced by the routing. It is therefore possible to influence properties already on the PC and thus tailor the paper for the later application.

For fiber composite technology, blanks could thus be produced which have fibers or reinforcements optimally deposited along the load paths. In addition to the mechanical properties, the pores and thus the fluid transport in the sample can also be influenced. The pores can also be influenced for filter applications.