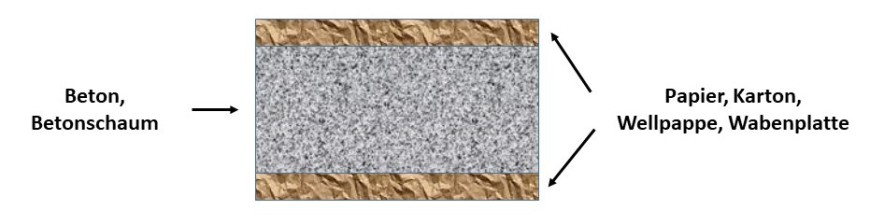

The aim of the project is to develop new, particularly energy-efficient concepts with composite materials based on paper, mineral building materials and plastics for functionalisation (e.g. for adhesion promoters or hydrophobisation). These concepts should be particularly suitable for constructing energy-efficient components, e.g. for building envelopes. Energy efficiency refers both to the thermal insulation properties during application in the building and during the production of the material itself and during the application of the materials.

Energy-efficient construction by composite materials with paper

Paper is a natural material obtained from renewable raw materials, which has been used for many centuries in the building industry (mainly in interior finishing). Paper can be produced cost-effectively in large quantities, is recyclable in many cases and offers a variety of possibilities for functionalisation in line with requirements thanks to the chemically reactive hydroxyl groups of cellulose. Compared to wood, paper can be tailored much better for specific applications. Despite these manifold possibilities, the possibility of using paper-based structures in combination with mineral materials in the construction industry has hardly been systematically investigated so far. There are a few examples of such composite materials, such as gypsum plasterboards or investigations on fibre-reinforced cement or concrete.