On the occasion of various anniversaries there have been numerous publications with historical content on the subject of paper manufacture. In the acknowledgements of former chair holders, too, one often finds explanations about the respective situation in the subject area, the study conditions and the equipment of the institute. This article attempts to present the history of the institute in chronological order, to link it with historical facts and to reflect on the terms of office of the few chair holders. The chronology is enriched by reports on significant influences on the development of the chair and the presentation of the main areas of work during the terms of office of the chair holders.

One may forgive the author if, due to the limited number of pages, not all details of the development of the subject area can be reproduced. With the presentation of the significant events at the Institute of Paper Manufacturing in the past 100 years and the quotation of the relevant literature references, the reader is able to deepen his knowledge [1].

The development of the paper industry

The flourishing industrialization in the production of paper around 1900 was the reason, after numerous negotiations between the Association of German Paper Manufacturers (V.D.P.), representatives of the Grand Ducal Hessian Government and the Grand Ducal Technical University of Darmstadt, to decide on 24/25 January 1905 to set up university courses for students of the paper industry [2]. The first lectures and exercises in the diploma examination regulations as optional subjects for the main examination in the mechanical engineering subject were “Paper production and its machines” and “Paper examination”. The communication of the study plan for students of the paper industry, as it was called at that time, added: “It is necessary to work practically one year in a paper machine factory and one year in a paper factory before entering the university. High school graduates from humanistic high schools are strongly advised to acquire the necessary skills in technical drawing during this time. For those who want to take the diploma examination, the one-year practical working time is a prerequisite for admission to the ”Diplom-Hauptprüfung“[3] ”But what were the reasons for introducing paper-related lectures and why did they choose Darmstadt of all places?

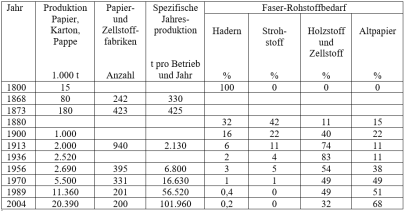

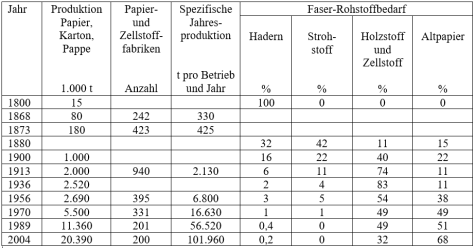

Let us first think back 100 years. Before 1900, paper production was still strongly influenced by craftsmanship. When the V.D.P. was founded in 1872, Gottlob KELLER had been inventing groundwood production for about 30 years and the production of wood pulp and straw pulp had also been known for some time. Nevertheless, Hadern was still mainly used as a raw material for paper production. With the development of efficient machines and processes, the increasingly expensive Hadern slowly became a much narrower manufacturing area, fine paper production. Around 1900, the processing of rags still accounted for 16 % of the total raw material requirement; in 1936 it was only 2 %. While the consumption of rags and straw as raw materials for paper production fell drastically from 1880 onwards, the use of wood in the form of ground wood pulp and cellulose as well as waste paper increased.

The industrial production of wood pulp using the calcium bisulphite process from MITSCHERLICH and the sulphate process with chemical recovery according to DAHL provided the papermaker with the universal paper pulp that could compensate for the lack of rags and straw. By the way, 66 companies in Germany produced sulphite pulp in 1880 according to the records of the Papiermacher-Berufsgenossenschaft in Mainz [4].

Table 1 clearly shows that paper production in Germany has increased more than 100-fold since 1873, while the number of companies has more than halved. With almost 1,000 companies, the paper industry flourished in terms of the number of companies before the First World War. The productivity of paper mills, calculated as average specific annual production, has benefited most from technological developments; it has increased by a factor of 240 since 1873.

The productivity increases in paper production were achieved by serious developments in paper machine construction. While the production of a paper machine in 1872 at a working width of 1.5 m and a speed of 5 – 35 m/min was still 1.5 to 2 t per day, the daily production could be increased by 1910 with machines of 3.5 m working width and speeds of up to 200 m/min to 35 to 40 t per day. Today, paper machine widths of 11 m, operating speeds of 2,000 m/min on twin wire formers and the resulting annual production of up to 600,000 t of paper on one machine are possible as peak values. At the same time, the paper machine was increasingly transformed from a multi-talent on which many different types of paper could originally be produced into a special machine for a certain type of paper.

Higher paper machine outputs initially required correspondingly larger fiber treatment units in the form of further developed Dutchmen and rollers. The introduction of trap stock systems for the reuse of waste water containing stock contributed to making paper production more ecological, but also more economical. The use of funnel-type material catchers reduced stock consumption by 5 – 10 %. The further development of calenders, rolling and cutting machines as well as the necessary ancillary operations such as the boiler house and steam power plant also contributed to technical progress in paper production [4]. Subsequently, pulpers and refiners for pulping and continuous grinding had to be invented. With the use of recovered paper as a raw material source, “highly-sophisticated” stock preparation plants with numerous cleaning machines developed. However, the enormous increases in production were not only due to larger and more powerful machines, but were also the result of the development of continuously operated machines and the introduction of measurement, control and regulation technology. Only modern process control technology makes it possible to operate even the largest plants with the least personnel expenditure from the control room of a company with high efficiency.

This increasing mechanization of paper production required specialized technical engineers – paper engineers – who had not previously been trained. In the 19th century, the change from manual paper production to industrial paper production took place slowly and then ever more rapidly. By the end of the 19th century, the V.D.P. had established that the “strong transformation of many paper mills into large enterprises” made it necessary to “call in suitable engineers and chemists to manage and control production” and to “provide special scientific training for their assistants”. [4] It was clear that paper production also required a scientifically sound working method and that the structured illumination of production processes required engineers who could combine knowledge of mechanical engineering, electrical engineering and chemistry. The circle of men who held this view vis-à-vis the Hessian government was headed by Dr. Adolf SCHEUFELEN, Councillor of Commerce from Oberlenningen, who is regarded as a co-founder of the field of paper engineering and remained faithful to his “child” as a helper and advisor until his death in 1941 [8]. It remains to be mentioned that the start of the field of paper engineering in 1905 was also financially supported by the V.D.P. with a total of 19,000 Marks in the first four years for the “purchase of mechanical equipment for teaching” [9]. It is also supportive to assume that at that time the paper factory owners were certainly at least benevolently, if not actively, in favour of the establishment of an adequate technical-scientific study programme for the qualified education of their sons.